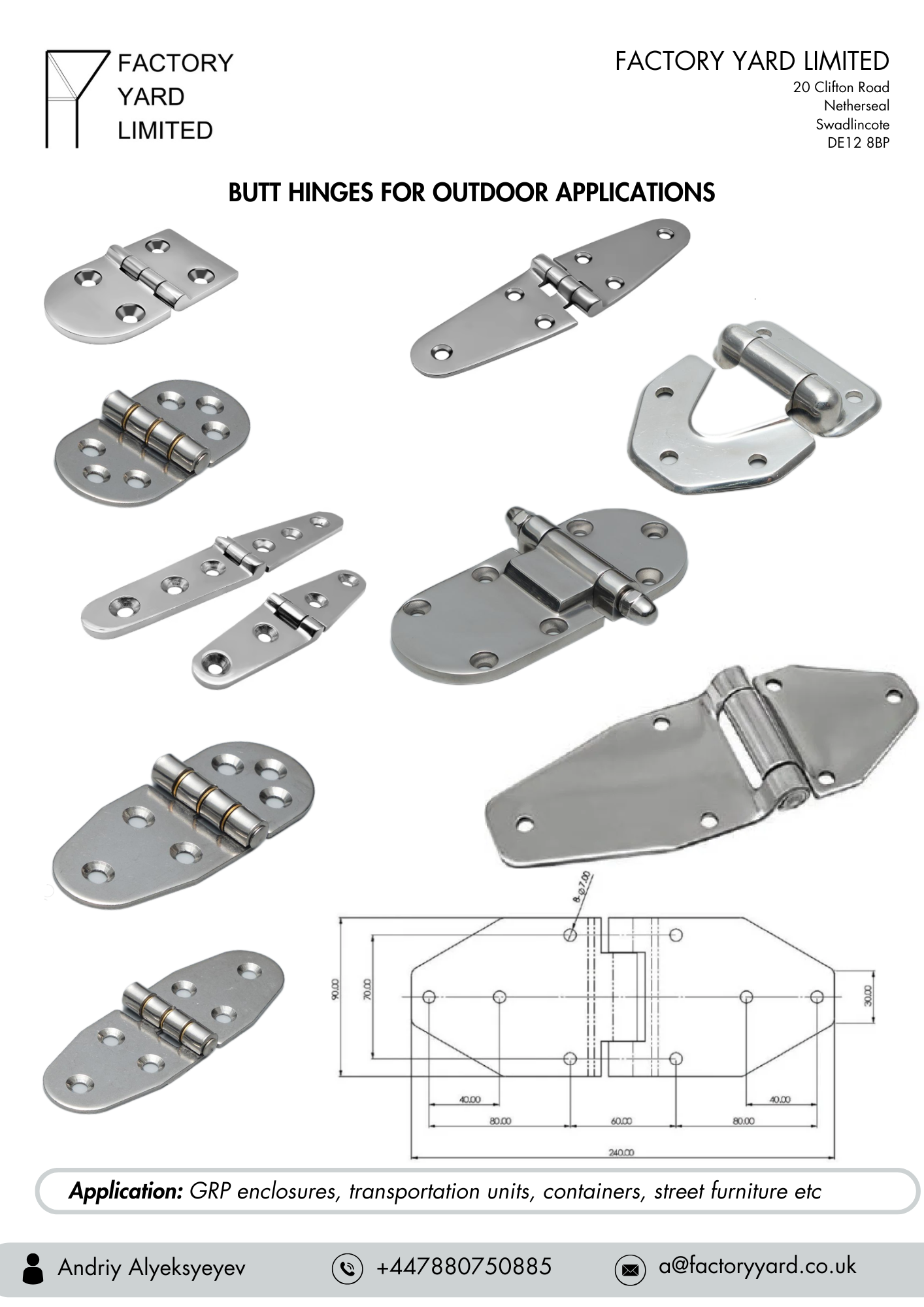

Industrial Butt Hinges for Outdoor Applications

Industrial Butt Hinges for Outdoor Applications

Industrial butt hinges designed for outdoor use must withstand harsh environmental conditions, including moisture, temperature variations, and corrosion. These hinges are typically made from stainless steel, aluminum, or zinc die-cast with protective coatings such as powder coating, chrome plating, or anodization for enhanced durability.

Key Features of Outdoor Industrial Butt Hinges

✅ Weather & Corrosion Resistant – Made from stainless steel, galvanized steel, or coated materials to resist rust and oxidation.

✅ Heavy-Duty Construction – Built to withstand high loads and frequent usage.

✅ Smooth 180°+ Rotation – Allows unrestricted access to doors, enclosures, and panels.

✅ Secure & Easy Installation – Available with pre-drilled holes or threaded studs for mounting.

✅ UV & Chemical Resistance – Suitable for exposure to sunlight, rain, and industrial chemicals.

Materials & Finishes for Outdoor Use

- Stainless Steel (304/316 Grade): Best for marine and outdoor applications due to its superior corrosion resistance.

- Zinc Die-Cast with Coating: Provides a balance between strength and cost, often powder-coated or chrome-plated for additional protection.

- Galvanized Steel: Features a zinc coating to prevent rust, making it suitable for industrial outdoor use.

- Aluminum: Lightweight and rust-resistant, often anodized for extended durability.

Applications of Outdoor Butt Hinges

✔ Electrical & Industrial Enclosures – Ensures long-lasting performance in outdoor control panels and switchgear cabinets.

✔ Heavy-Duty Gates & Doors – Used in security gates, access panels, and utility doors.

✔ Marine & Coastal Installations – Stainless steel versions resist saltwater corrosion.

✔ Transportation & Trailers – Provides durability for vehicle storage compartments and access panels.

✔ Outdoor Equipment & Machinery Covers – Protects sensitive equipment from environmental elements.