Quarter-Turn Latch Inserts Explained: Types, Applications, and How to Choose the Right One

Quarter-turn latches are widely used in industrial enclosures because of their simplicity, reliability, and fast access. While the latch body and fixing hole can remain the same, the insert type determines who can access the enclosure, how secure it is, and where it should be used.

Selecting the correct insert is a key part of enclosure design, especially for electrical, telecom, utility, and outdoor applications.

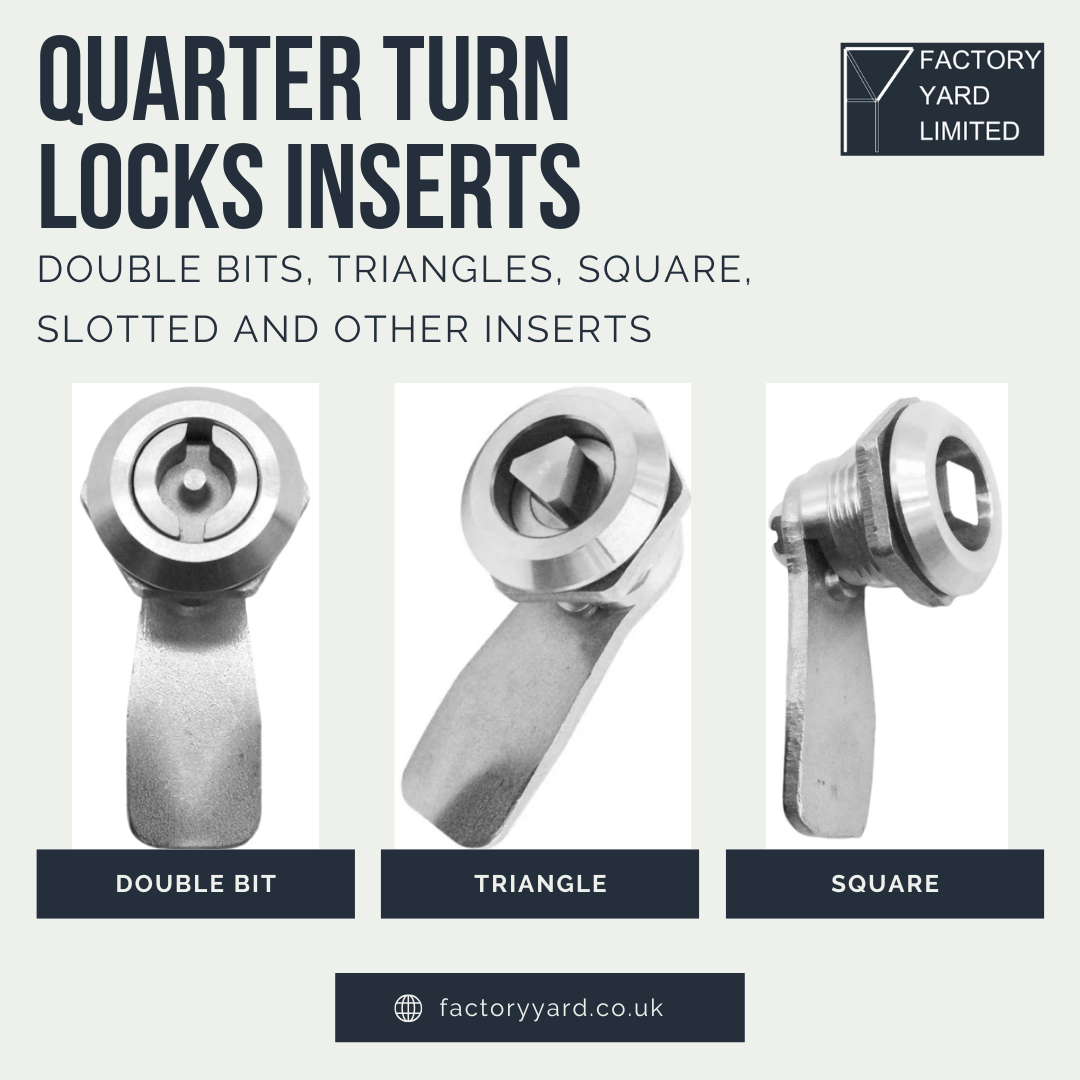

1. Double-Bit Insert

Application:

Electrical cabinets, control panels, industrial enclosures

Why use it:

The double-bit insert is one of the most common solutions for controlled access. It requires a dedicated double-bit key, making it suitable for trained personnel only.

Advantages:

-

Good security level

-

Standardised across many industries

-

Widely accepted for electrical enclosures

2. Triangle Insert

Application:

Utility cabinets, street furniture, infrastructure enclosures

Why use it:

Triangle inserts are commonly used by municipalities and utility companies. Service teams carry standardized triangle keys, allowing fast and secure access in public environments.

Advantages:

-

Standard utility access

-

Good balance between security and accessibility

-

Ideal for outdoor and public installations

3. Square Insert

Application:

Industrial machinery, control panels, service enclosures

Why use it:

Square inserts are popular in industrial settings where maintenance teams use standard tools. They offer simple operation and good mechanical strength.

Advantages:

-

Robust and durable

-

Easy access for maintenance teams

-

Suitable for indoor and industrial environments

4. Slotted Insert

Application:

Low-security cabinets, internal enclosures, service panels

Why use it:

Slotted inserts allow access with a flat screwdriver or tool. They are best used where quick access is required and security is not critical.

Advantages:

-

Fast and easy operation

-

Cost-effective solution

-

Ideal for non-critical access points

5. Hex (Allen) Insert

Application:

Industrial equipment, machine housings, OEM assemblies

Why use it:

Hex inserts require an Allen key, adding a basic level of access control while remaining easy for technicians to use.

Advantages:

-

Compact design

-

Better security than slotted inserts

-

Clean industrial appearance

6. Wing Insert

Application:

Service panels, maintenance hatches, light-duty enclosures

Why use it:

Wing inserts can be operated by hand, without tools. They are suitable where frequent access is needed and security is not a concern.

Advantages:

-

Tool-free operation

-

Fast opening and closing

-

Ideal for internal access

7. Special and Custom Inserts

Application:

Project-specific enclosures, OEM designs, restricted access systems

Why use it:

Custom inserts allow manufacturers to control access while keeping the same quarter-turn latch body and cut-out. This is useful for branded or restricted-access projects.

Advantages:

-

Tailored access control

-

Standard latch body, custom security

-

Flexible design options

Choosing the Right Insert for Your Enclosure

When selecting a quarter-turn latch insert, consider:

-

Required security level

-

Indoor or outdoor installation

-

Public or restricted access

-

Frequency of opening

-

Industry standards or utility requirements

By choosing the correct insert, manufacturers can standardize enclosure designs while controlling access efficiently and safely.

Conclusion

Quarter-turn latch inserts play a crucial role in enclosure security and usability. From high-control double-bit inserts to utility triangle keys and simple slotted access, each insert type serves a specific purpose.

Understanding these options allows enclosure manufacturers to design smarter, safer, and more efficient locking systems without changing the latch body or fixing hole.